40kHz Full Wave Horns

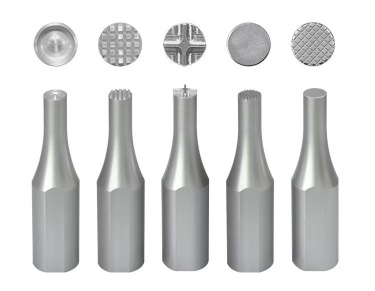

40kHz full wave welding head is a key component used in ultrasonic welding equipment, usually with the following characteristics:

The working frequency is 40kHz, which can convert high-frequency electrical energy into mechanical vibration energy. Its frequency band characteristics give it certain advantages in the welding process, such as high welding accuracy and low heat impact.

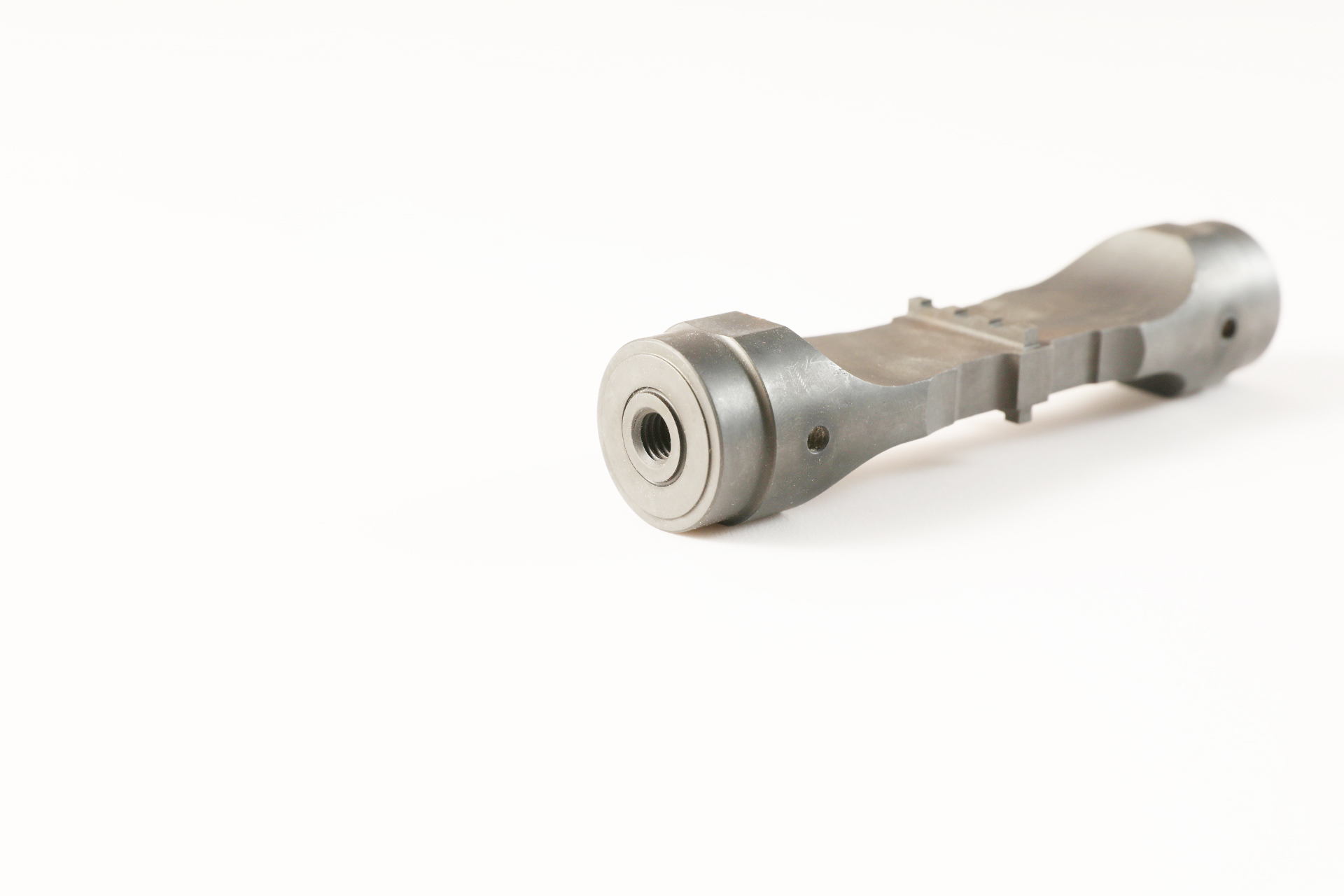

In terms of structure, it is generally made of high-quality materials, such as titanium alloy, to ensure good durability and stability. Meanwhile, in order to meet different welding needs, there may be various shapes and sizes designed.

The amplitude of the welding head is relatively stable, which helps to ensure the consistency and reliability of welding quality. It usually achieves a high level of service life and ease of adjustment, which can effectively improve production efficiency

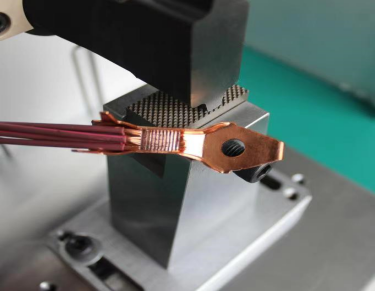

The welding method of 40kHz full wave welding head is ultrasonic welding. Its principle is to convert the mains electricity into high-frequency electronic pulses, which are then converted into high-frequency mechanical vibrations through transducers. The welding head transmits them to the surface of the welded workpiece, causing the workpiece to rub against each other under 40000 cycles of pressure per second, thereby forming a clean and controllable diffusion welding under pressure, achieving reliable metallurgical fusion.

In practical applications, the 40kHz full wave welding head is mainly used for metal welding, especially in some situations that require high welding accuracy and quality, such as the production and production of lithium batteries, which can be used to achieve the welding of copper foil and copper strip, copper foil and nickel strip.

To ensure product quality, each welding head is generally tested for size, frequency, loss power, and other factors before leaving the factory. In addition, some welding heads are also compatible and can be installed and used on different devices.

Previous: No More

Next: OX Horn